Class X: Chapter 6 (Manufacturing Industries)

Objectives and Goals:

(a) Define the term Manufacturing and Industries.

(b) Three types of economic activities (i.e. Primary, Secondary and Tertiary).

(c) Importance of Manufacturing.

(d) Contribution of Industry to National Economy.

(e) Industrial Location (Factors effecting the location of an Industry).

(f) Industrial Market Linkage (The Industrial System).

(g) Classification of Industries (i.e. On the basis of Raw Materials, On the basis of Investment: Large Scale Industries, Small Scale Industries and On the basis of Ownership: Private Sector Industries, Public Sector Industries, Joint Sector Industries, Co-operative Sector Industries).

(h) Agro Based Industries (Textile Industry: Cotton & Jute, Sugar Industry)

(i) Mineral Based Industries (Iron & Steel Industry, Automobile Industry, Information Technology & Electronics Industry)

(j) Industrial Pollution and Environmental Degradation: Air Pollution, Water Pollution, Thermal Pollution, Noise Pollution).

(k) Control of Environmental Degradation.

(l) National Thermal Power Corporation (NTPC)

There are three types of economic activities. These are:

1. Primary Activities: Connected with extraction and production of natural resources like forestry, agriculture, mining, animal husbandry, etc.

2. Secondary Activities: Connected with processing and manufacturing. They get raw material from the Primary sector. When the primary product is processed into a secondary product, its utility and value is increased.

3. Tertiary Activities: Provides support to Primary and Secondary sectors through services, e.g. transportation, banking, tourism, etc.

MANUFACTURING: Production of goods in large quantities after processing from raw material to more valuable products is called "Manufacturing".

INDUSTRY: Industry refers to an economic activity that is concerned with the production of goods, extraction of minerals or the provision of services.

THE ECONOMIC STRENGTH OF A COUNTRY IS MEASURED BY THE DEVELOPMENT OF MANUFACTURING INDUSTRIES.

IMPORTANCE OF MANUFACTURING INDUSTRIES:

(a) Industrial growth helps in modernising the agricultural activities by providing machinery, chemicals, irrigation facilities, insecticides, pesticides, etc..

(b) Industrial growth helps in reducing the unemployment and poverty.

(c) Industrial growth can earn foreign exchange by exporting the finished goods and thus, can expand its trade and commerce.

(d) Any country with high level of manufacturing activities becomes prosperous.

CONTRIBUTION OF INDUSTRY TO NATIONAL ECONOMY:

(a) The share of manufacturing sector in the GDP (Gross Domestic Product) has been stagnant at 17% over the last two decades.

(b) The total contribution of industry to the GDP is 27% out of which 10% comes from mining, quarrying, electricity and gas.

(c) The growth of the manufacturing sector had been 7% in the last decade. Since 2003, the growth rate has been 9 to 10% per annum. The desired growth rate over the next decade is 12%.

(d) The National Manufacturing Competitiveness Council (NMCC) has been set with the objectives of improving productivity through proper policy interventions by the government and renewed efforts by the industry.

INDUSTRIAL LOCATION

Factors effecting the location of an Industry:

(a) Physical Factors

(b) Human Factors

(c) Key to decision of industrial location is "LEAST COST".

(d) Government policies and specialized labours also influence the location of industry.

• Agglomeration Economies: Many Industries tend to come together to make use of the advantages offered by the urban centre's known as agglomeration economies. Gradually, a large industrial agglomeration takes place.

• Industrialization leads to Urbanization.

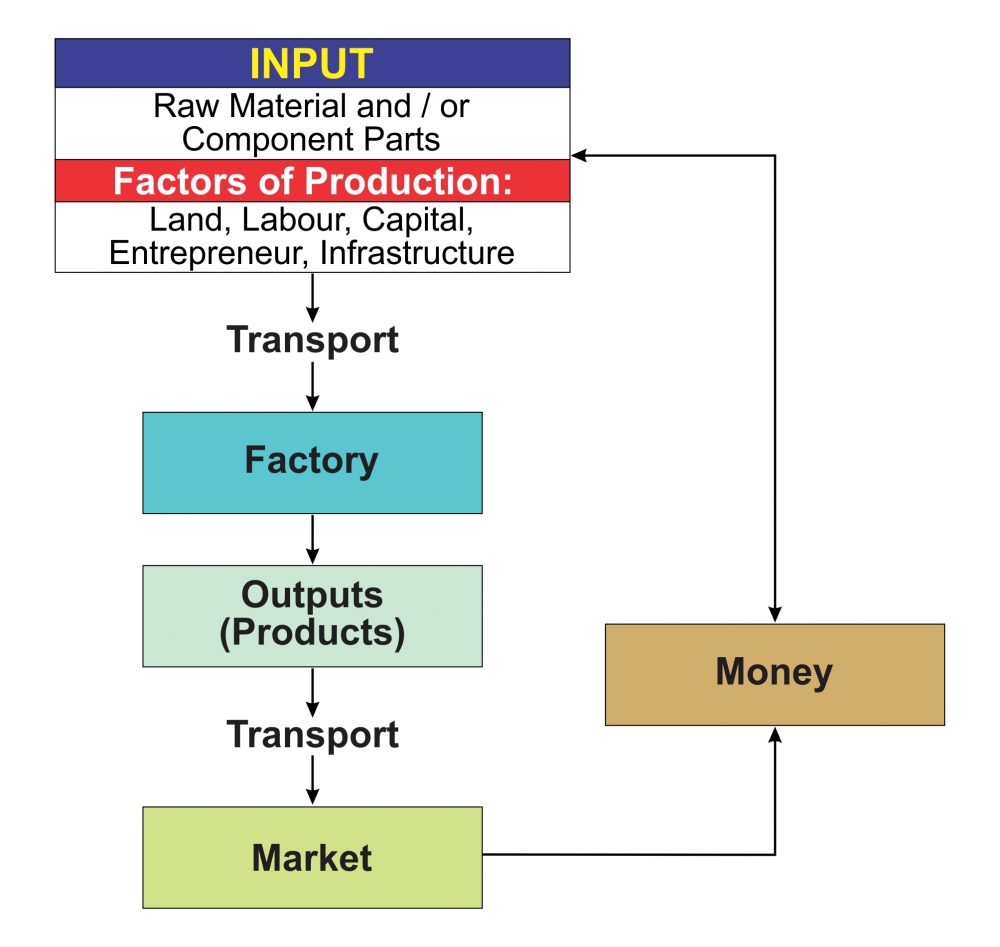

INDUSTRIAL SYSTEM

• An industrial system consists of inputs, processes and outputs.

Input: Raw materials, labour, costs of land, transport, power and other infrastructure.

Process: All activities that convert the raw material into finished products.

Output: End/ Final/Finished product and the income earned from it.

INDUSTRY – MARKET LINKAGE

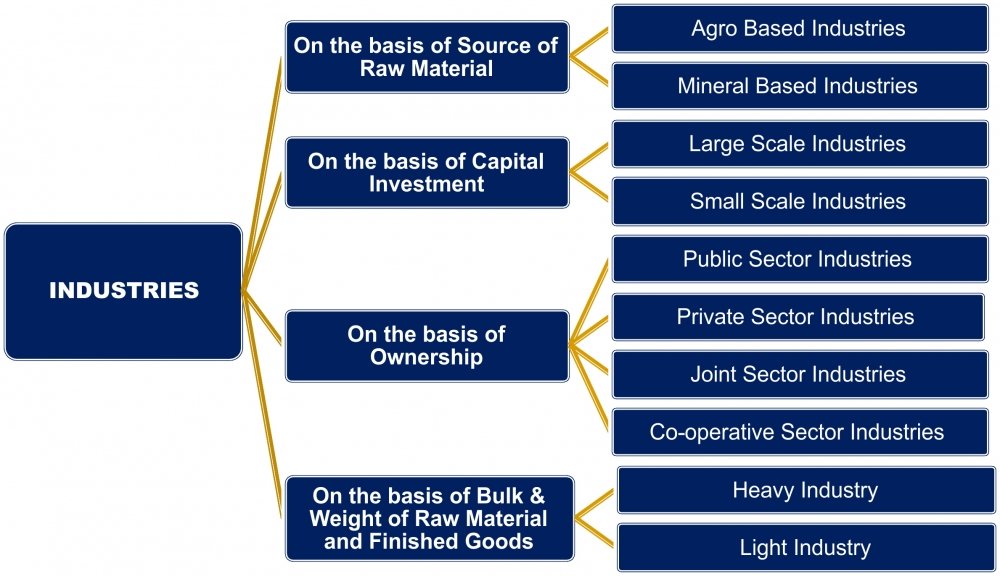

CLASSIFICATION OF INDUSTRIES:

1. On the basis of Raw Materials:

These types of industries are classified depending on the type of raw materials they use.

(a) Agro Based Industries: Use plant and animal based products as their raw materials. E.g. Food processing, vegetable oil, cotton textile, dairy products, etc.

(b) Mineral Based Industries: Primary industries that use mineral ores as their raw materials. The products of these industries feed other industries. Iron made from iron ore is the product of mineral based industry. E.g. Iron& Steel, Cement, Machine Tools, etc.

According to their main role:

1. Basic or Key Industries: These industries supply their products or raw materials to manufacture other goods, e.g. iron and steel, copper smelting, aluminium smelting, etc.

2. Consumer Industries: These industries produce goods which are directly used by consumers, e.g. sugar, paper, electronics, soap, etc.

2. On the basis of Investment:

These types of industries are classified depending on the amount of capital invested, number of people employed and the volume of production.

(a) Large Scale Industries: In India, on an industry, if the capital invested is more than 1 crore, then it is called Large Scale Industry. e.g. Iron & Steel Industries, Automobile Industries, etc.

(b) Small Scale Industries: In India, on an industry, if the capital invested is less than 1 crore, then it is called Small Scale Industry. E.g. Silk weaving, Food processing industries, etc.

3. On the basis of Ownership:

(a) Private Sector Industries: Owned and operated by individuals or a group of individuals. e.g. Bajaj Auto, Reliance, etc.

(b) Public Sector Industries: Owned and operated by the government. e.g. Hindustan Aeronautics Limited (HAL), Bharat Heavy Electronics Ltd. (BHEL), SAIL, etc.

(c ) Joint Sector Industries: Owned and operated by the state and individuals or a group of individuals. e.g. OIL (Oil India Ltd.), Maruti Udyog Limited., Gujarat State Fertilizers, Cochin Refineries, etc.

(d) Co-operative Sector Industries: Owned and operated by the producers or suppliers of raw materials, workers or both. Mutually they get the resources and share the profit and losses. e.g. Sugar industry in Maharashtra, Coir industry in Kerala, etc.

4. On the basis of the Bulk and Weight of Raw Materials and Finished Goods:

(a) Heavy Industries: Use heavy and bulky raw material and produce heavy goods. E.g. Iron and Steel Industry.

(b) Light Industries: Use light raw material and produce light goods. E.g. Electrical Industries.

AGRO BASED INDUSTRIES

Following are some of the type of industries using agricultural raw material:

(a) Textile Industries: Cotton, Jute, Silk, Woollen, etc.

(b) Sugar and Edible Oil, etc.

TEXTILE INDUSTRY

(a) The textile industry contributes 14% to industrial production in India.

(b) 35 million persons are directly employed in the textiles industry in India.

(c) In terms of employment generation, this industry is the second largest after agriculture.

(d) It earns approximately 24.6% of the foreign exchange.

(e) The contribution of textiles industry to GDP is 4%.

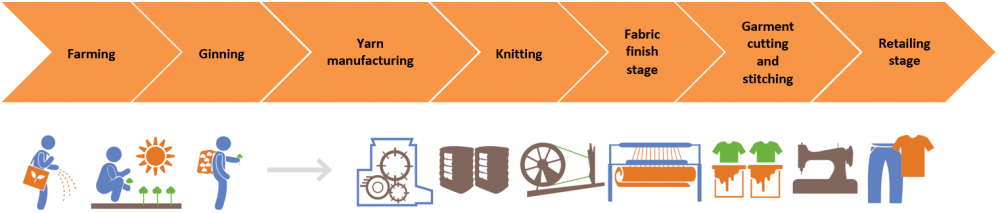

(f) This is the only industry in the country which is self-reliant and complete in the value chain.

Cotton Textiles:

(a) Cotton textiles were traditionally produced with hand spinning and handloom weaving techniques.

(b) Power-looms came into use after the 18th century. During the colonial period, the competition of mill-made cloth from England destroyed the Indian textiles industry.

(c) By November 2011 there were 1946 cotton and synthetic textile mills in India.

(d) Almost 80% of them are in the private sector. The rest are in the public sector and cooperative sector.

(e) Additionally, there are several thousand small factories with four to ten looms.

Location of Cotton Textile Industry:

(a) This industry was earlier concentrated in the cotton belt of Maharashtra and Gujarat.

(b) Availability of raw materials, port facilities, transport, labour, moist climate, etc. were in favour of these locations.

(c) The industry provides a source of livelihood to farmers, cotton boll pluckers and workers engaged in ginning, spinning, weaving, dyeing, designing, packaging, tailoring and sewing.

(d) This industry supports many other industries; like chemical and dyes, mill stores, packaging materials and engineering works.

(e) Spinning still continues to be centralized in Maharashtra, Gujarat and Tamil Nadu.

(f) However, weaving is highly decentralized and there are many weaving centers in the country.

(g) India has world class production in spinning but weaving supplies low quality of fabrics as it cannot use much of the high quality yarn produced in the country.

(h) The handspun khadi provides large scale employment to weavers in their homes as cottage industry.

(i) India exports cotton yarn to Japan. Cotton goods are also exported to USA, UK, Russia, France, East European countries, Nepal, Singapore, Sri Lanka and African countries.

(j) At around 34 million, India has the second largest installed capacity of spindles in the world; after China.

(k) India accounts for one fourth of the world trade in cotton yarn. However, India's share in garment trade in the world is only 4%.

(l) Our spinning mills are globally competitive and can use all the fibres we produce. But the weaving, knitting and processing units cannot use much of the high quality yarn produced in the country.

Problems faced by cotton textile industries in India:

(a) Unpredictable power supply.

(b) Obsolete machinery.

(c) Low output of labour.

(d) Stiff competition with the synthetic fiber.

Jute Textiles:

(a) India is the largest producer of raw jute and jute goods in the world.

(b) It is the second largest exporter of jute; after Bangladesh.

(c) In 2010-11 there were 80 jute mills in India.

(d) Most of these mills are located in West Bengal; mainly along the bank of river Hooghly.

(e) The jute industry is in a narrow belt which is 98 km long and 3 km wide.

Location advantages of Hooghly basin:

(a) Proximity of the jute producing areas.

(b) Inexpensive water transport.

(c) Good rail and road network.

(d) Abundant water for processing raw jute.

(e) Cheap labour from West Bengal, Bihar, Orissa and Uttar Pradesh.

(f) The jute industry directly supports 2.61 lakh workers.

(g) It also supports 40 lakh small and marginal farmers who are engaged in cultivation of jute and mesta.

(h) Jute industry is facing challenge from synthetic fiber and also from other competitors like Bangladesh, Brazil, Philippines, Egypt and Thailand. But the internal demand has been rising because of government policy of mandatory use of jute packaging.

(i) The National Jute Policy was formulated in 2005 with an objective to increase productivity, improve quality and ensure good prices for the jute farmers.

(j) Due to growing global concern for environment friendly and biodegradable material; the future of jute looks bright.

(k) USA, Canada, Russia, UAE, UK and Australia are the main markets.

Sugar Industry:

(a) India is the second largest producer of sugar in the world.

(b) It is the largest producer of gur and khandsari.

(c) There are over 460 sugar mills in the country.

(d) They are spread over Uttar Pradesh, Bihar, Maharashtra, Karnataka, Tamil Nadu, Andhra Pradesh, Gujarat, Punjab, Haryana and Madhya Pradesh.

(e) Sixty percent mills are in UP and Bihar.

(f) This industry is seasonal and hence is more suited to the cooperative sector.

(g) In recent years, there has been a growing tendency to shift and concentrate in the southern and western states; especially in Maharashtra.

(h) The cane produced in this region has higher sucrose content. The cooler climate of this region ensures a longer crushing season.

Challenges for Sugar industry:

(a) Seasonal nature of industry.

(b) Old and inefficient methods of production.

(c) Transport delay and the need to maximize the use of baggase are the major challenges for this industry.

MINERAL BASED INDUSTRIES

Iron & Steel Industry

(a) This is basic industry.

(b) These industries are the feeder industry whose products are used as raw material for other industries.

(c) Due to this, production and consumption of steel is often regarded as the index of a country's development.

(d) India is 9th among the world crude steel producers and produces 32.8 million tons of steel.

(e) India is the largest producer of sponge iron. But per capita consumption of steel is only 32 kg per annum.

(f) At present, there are 10 primary integrated steel plants in India. Additionally, there are many mini steel plants in the country.

(g) SAIL (Steel Authority of India Limited) is the major public sector company in this sector, while TISCO (Tata Iron and Steel Company) is the major private sector company in this industry.

(h) Most of the iron and steel industries are in the Chotanagpur plateau region. This region has plenty of low cost iron ore, high grade raw materials, cheap labour and good connectivity through railways and roadways.

Reasons for underperformance of Iron and steel Industry in India:

(a) High cost and limited availability of coking coal.

(b) Low productivity of labour.

(c) Erratic energy supply.

(d) Poor infrastructure.

Automobile Industry

(a) Almost all types of vehicles are manufactured in India.

(b) After liberalization in 1991, many automobile manufacturers set up their base in India.

(c) With the launch of contemporary models, India became an attractive market for automobiles.

(d) At present, there are 15 manufacturers of cars and multi-utility vehicles, 9 of commercial vehicles, 14 of two and three-wheelers.

(e) Delhi, Gurgaon, Mumbai, Pune, Chennai, Kolkata, Lucknow, Indore, Hyderabad, Jamshedpur, Bangalore, Sanand, Pantnagar, etc. are the major centers of automobile industry.

Information Technology and Electronics Industry

(a) Bangalore is often termed as the electronic capital of India.

(b) Mumbai, Pune, Delhi, Hyderabad, Chennai, Kolkata, Lucknow and Coimbatore are the other important centers.

(c) There are 18 software technology parks in the country and they provide single window service and high data communication to software experts.

(d) This industry had generated a large number of employments.

(e) Upto 31 March 2005, over one million persons were employed in the IT industry. Because of fast growth of BPO (Business Process Outsourcing); this sector has been a major earner of foreign exchange.

INDUSTRIAL POLLUTION AND ENVIRONMENTAL DEGRADATION

• Industries are responsible for majorly four types of pollution: Air, Water, Land and Noise.

• The polluting industries also include thermal power plants.

(a) Air Pollution: High proportion of carbon dioxide, sulphur dioxide and carbon monoxide create air pollution. Suspended particulate matters also create problems. Smoke is emitted from chimneys of various factories. Some industry also pose the risk of leak of hazardous chemicals; the way it happened during the Bhopal Gas Tragedy. Air pollution has adverse effect on human health, animals, plants, buildings, and the atmosphere as a whole.

(b) Water Pollution: Organic and inorganic industrial wastes and effluents cause water pollution. Paper, pulp, chemical, textile, dyeing, petroleum refineries, tanneries, etc. are the main culprits of water pollution.

(c) Thermal Pollution: It occurs when hot water from factories or thermal plants is drained into rivers and ponds before cooling. This plays havoc with the aquatic life.

Waste from nuclear power plants contains highly radioactive materials and it needs to be properly stored. Any leakage of radioactive material can cause short term and long term damages to humans as well as to other life forms.

(d) Noise Pollution: Noise pollution can result in constant irritation, hypertension and hearing impairment. Factory equipments, generators, electric drills, etc. are the major sources of noise pollution.

Preventing Environmental Degradation by Industry:

(a) Industries are responsible for majorly four types of pollution: Air, Water, Land and Noise.

(b) Water should be reused and recycled in the industry.

(c) This will help in minimizing the use of freshwater.

(d) Rainwater harvesting should be promoted.

(e) Hot water and effluents should be treated before being released in rivers and ponds.

-----x-----X-----x-----